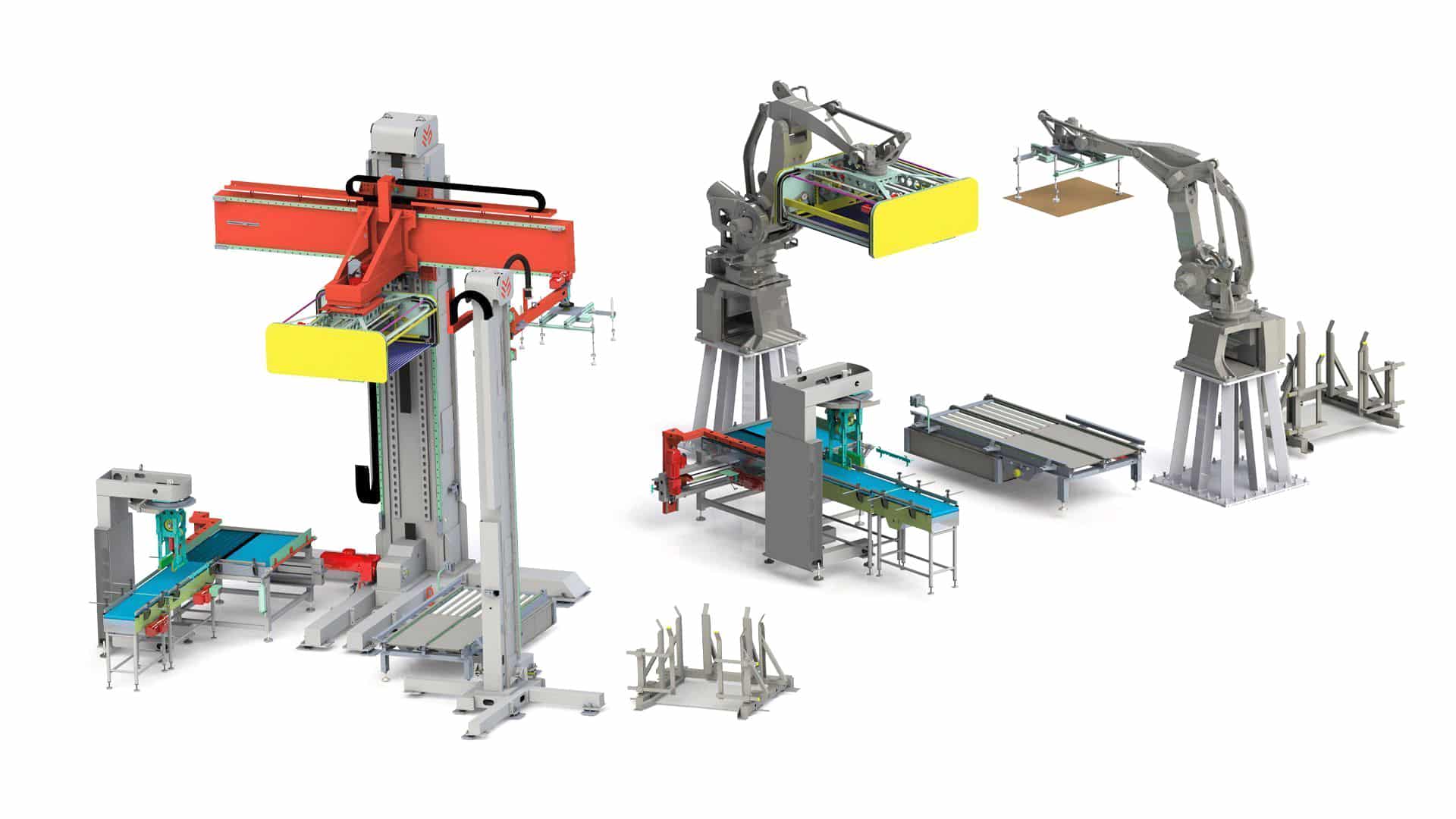

Our palletizing systems are designed with a modular concept that includes various types of palletizers, all configurable with interchangeable gripper heads. This approach enables us to deliver fully customized solutions, with applications specifically tailored to the requirements of each industry.

All our palletizers ensure:

> Maximum application and layout configuration flexibility.

> High efficiency.

> Accessibility for cleaning activities and maintenance.

The various pick-up heads enable management of a wide range of products with full reliability, ensuring pick and place operation precision and integrity of the product being processed. Depending on requirements, the heads can also be equipped with equipment for handling interlayers, pallets and frames

> Maximum layout configuration flexibility.

> Simple installation.

> Format change directly from HMI.

> Reduced maintenance thanks to the use of toothed belts.

> Anti-fall system for all the hanged loads.

> High accessibility.

> High production capacity with low level product infeed.

> Format change directly from HMI.

> Reduced maintenance thanks to the use of toothed belts.

> Anti-fall system for all the hanged loads.

> MTBF: 60,000 hours.

> High production capacity.

> Possibility to work simultaneously on several stations.

> Maximum layout configuration flexibility.

> Format change directly from HMI.

> Simple installation.Low maintenance costs.

> High accessibility.

>MTBF: 60,000 hours.

> High production capacity.

> Maximum flexibility and reliability in product handling.

> Versatile layout configuration.

> Reduced footprint.

> Format change directly from HMI.

> Low maintenance thanks to the few moving mechanical components.

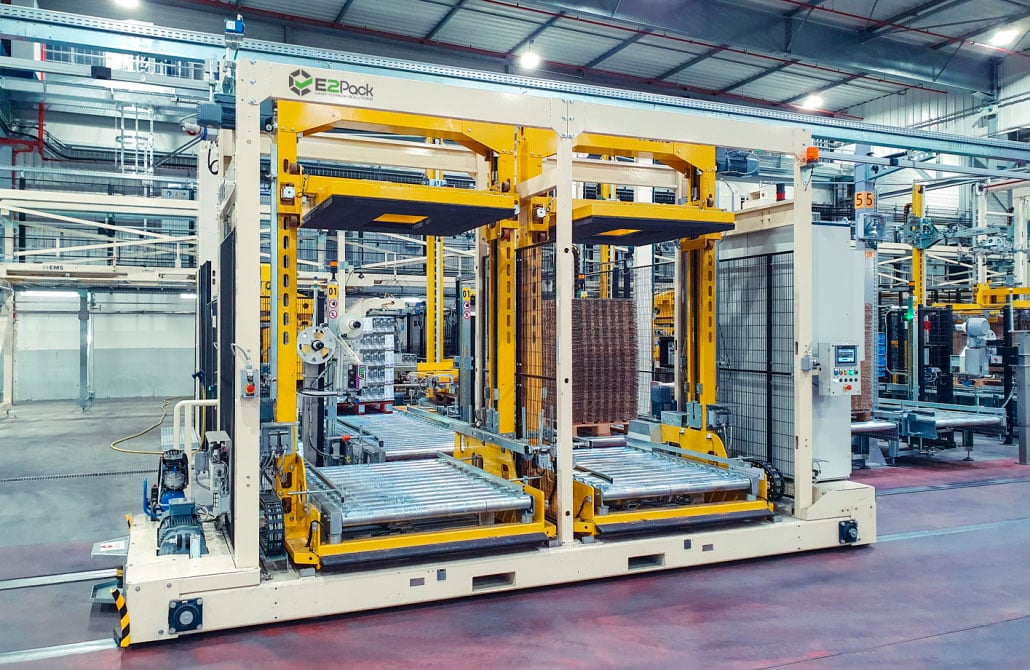

> Total application flexibility and high operational autonomy thanks to the three independent handling units with the variable opening gripper and the E2Pack Layer Optimizer software.

> Multiple simultaneous handling – up to 6 product units.

> Product integrity is guaranteed by full control of the applied pressure.

> Instant and automatic format change via HMI.

> Optimized distribution of the workload on the manipulators for high efficiency.

> Reduced maintenance thanks to the implementation of brushless motors.

> MTBF: 60,000 hours.

> High reliability.Multiple simultaneous handling – up to 8 product units.

> Product integrity is guaranteed by full control of the applied pressure.

> Instant and automatic format change via HMI.

> Fanuc drive for gripper opening and closing.

> Up to 4 pallet stations.

> Capacity up to 1500 kg for each pallet station.

> Load stability guaranteed by top pressure unit.

> High safety guaranteed by PLS, bumper and telescopic approach system for pallets loading/unloading.

> High speed and low noise thanks to vulkolan wheels.

> Maximum layout configuration flexibility.

> Simple installation.

> Format change directly from HMI.

> Reduced maintenance thanks to the use of toothed belts.

> Anti-fall system for all the hanged loads.

> High accessibility.

> Maximum layout configuration flexibility.

> Simple installation.

> Format change directly from HMI.

> Reduced maintenance thanks to the use of toothed belts.

> Anti-fall system for all the hanged loads.

> High accessibility.

> MTBF: 60,000 hours.

> High production capacity.

> Possibility to work simultaneously on several stations.

> Maximum layout configuration flexibility.

> Format change directly from HMI.

> Simple installation.

> Low maintenance costs.

> High accessibility.

> Tray interlocking system facing outwards so as to not obstruct the internal area and compromise product insertion (patent pending).

> User-friendly.

> Facilitated automatic or manual adjustment.

> Maximum layout configuration versatility.

> High accessibility.

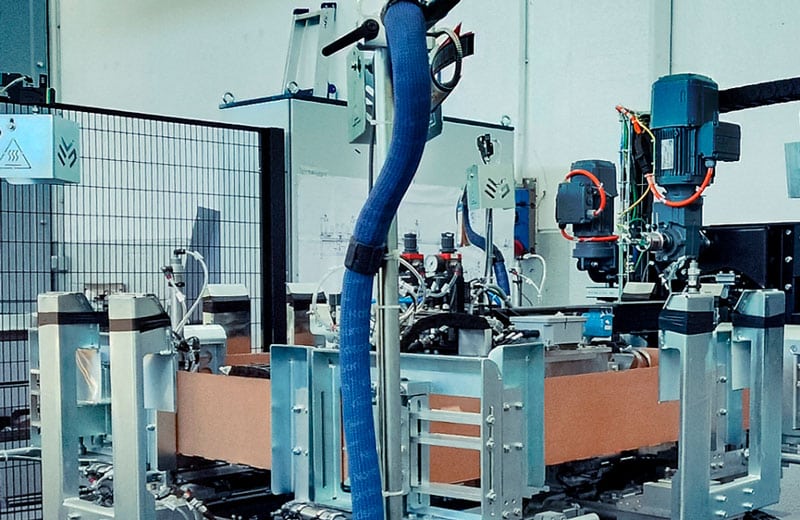

> Traditional sweeping operation.

> Assisted sweeping operation.

> Inflating tubes/pincers and row approaching: mainly used for oval/conical bottles, for which accumulation is to be avoided.

> Inflating/mechanical fingers/pick-up systems and row approaching: mainly used for special shaped jars, for which accumulation is to be avoided.

> Fingers/cups/tulipes and bottle spacing: mainly used in case of palletization inside thermoformed layer separators or partitions.

> Up to 4 pallet stations.

> Capacity up to 1500 kg for each pallet station.

> Load stability guaranteed by top pressure unit.

> High safety guaranteed by PLS, bumper and telescopic approach system for pallets loading/unloading.

> High speed and low noise thanks to vulkolan wheels.

> Speed and efficiency

> Reliability in continuous operation

> Compact and ergonomic design

> Reduced downtime for product changeovers

> Flexibility

> Reduced footprint

> High adaptability to different packaging formats

> Energy-efficient operation

> Robust and durable structure

> Great flexibility

> Low maintenance

> High efficiency

> Easy reconfiguration

> Safe and user-friendly operation

> Long-term reliability