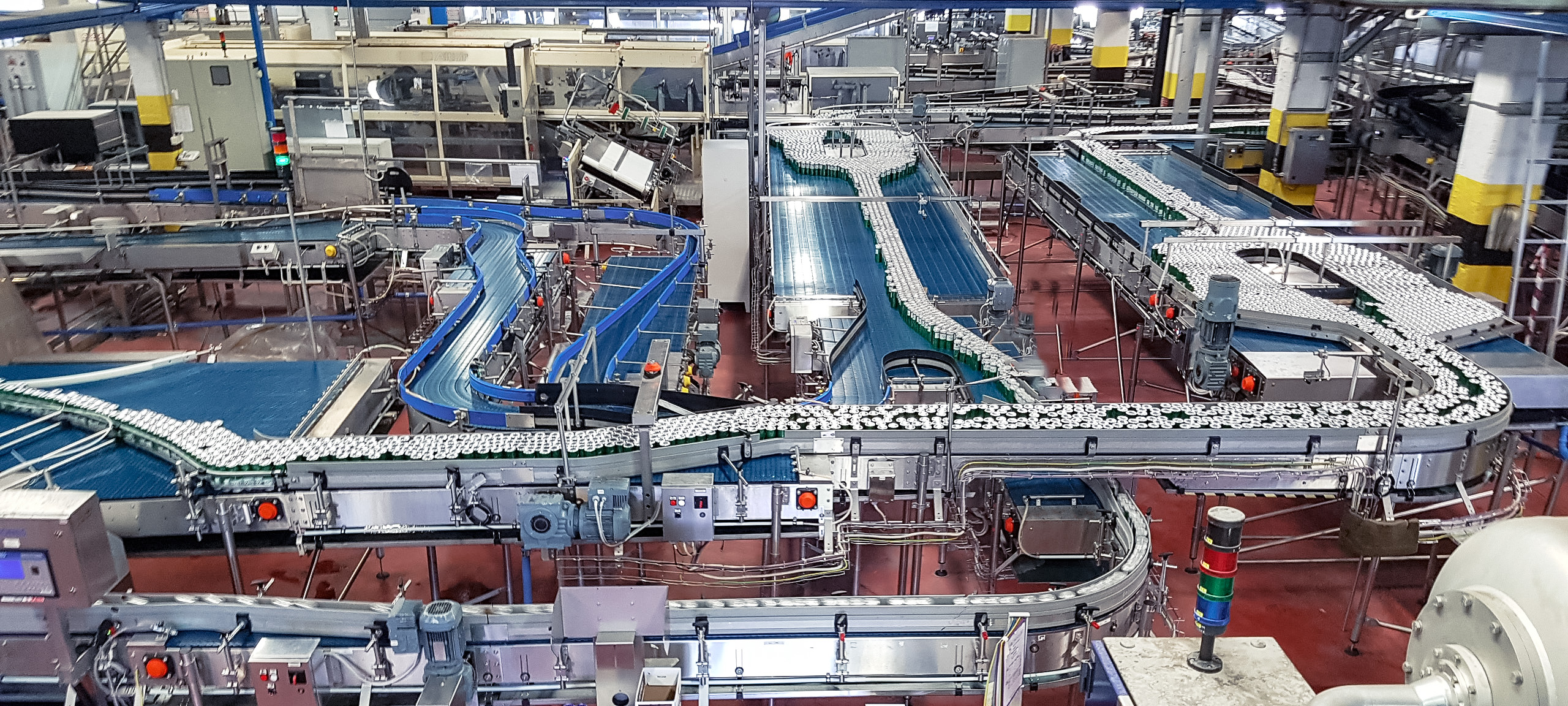

E2Pack provides a complete engineering service for the construction of conveying lines for:

- Empty, full and packaged PET.

- Aluminum and tinplate cans.

- Empty, full and packaged glass containers.

- HDPE containers, bins, crates, cartons, trays, bundles and jerry cans, pouches, etc.

Our lines use different conveying systems to guarantee the optimal solution based on the type of product processed, plant layout and capacity.

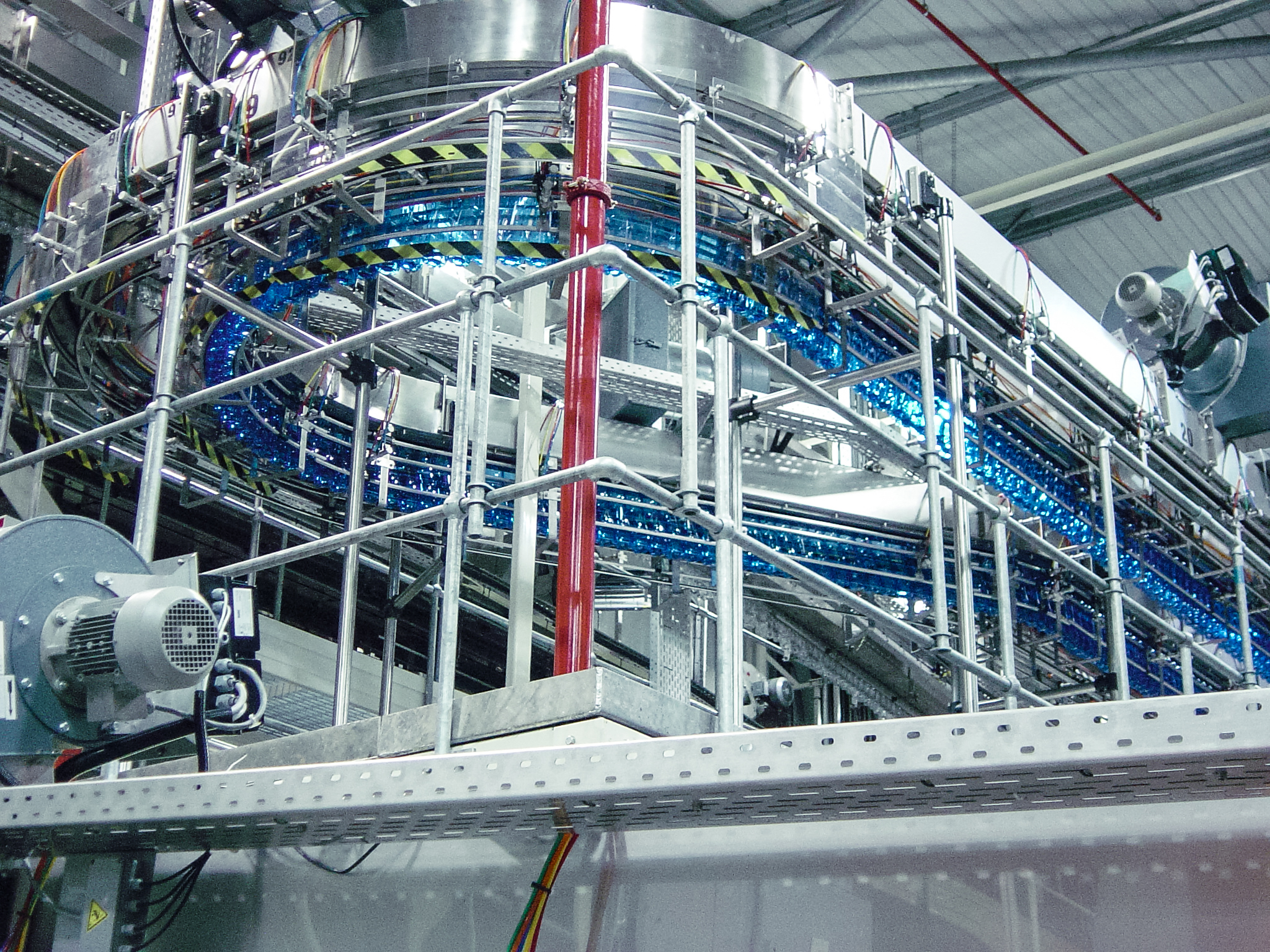

EMPTY PET AND HDPE

Air or vacuum conveying systems for empty PET containers with production capacity up to 1500 containers per minute.

FULL PET AND HDPE

Air or vacuum conveying systems for full PET and HDPE containers with production capacity up to 1500 containers per minute.

EMPTY GLASS

Conveying systems for empty glass containers (jars and bottles) with production capacity up to 1000 containers per minute.

FULL GLASS

Conveying systems for full glass containers (jars and bottles) with production capacity up to 1500 containers per minute.

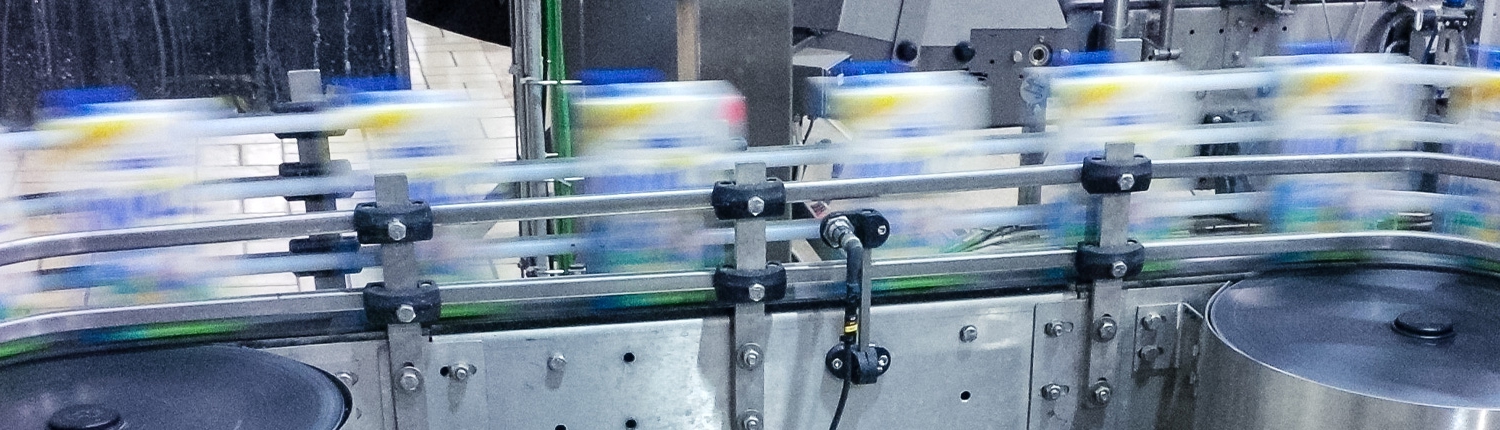

TINPLATE CANS

Conveying systems for empty and full tinplate cans with production capacity up to 2000 containers per minute.

ALUMINUM CANS

Conveying systems for empty and full aluminum cans with production capacity up to 2000 containers per minute.

BRICK

Conveying systems for brick products with production capacity up to 500 containers per minute.

LARGE PET, HDPE AND TINPLATE CONTAINERS

Conveying systems for large empty and full PET, HDPE and tinplate containers with production capacity up to 300 containers per minute.

PLASTIC POUCHES

Conveying systems for plastic pouches with production capacity up to 500 containers per minute.

CONTAINERS PACKAGED IN BUNDLES, CARTONS, CRATES AND TRAYS

Conveying systems for empty and full containers packaged in bundles, cartons, crates and trays with production capacity up to 300 units per minute.